In the process of pharmaceutical development, the application of powder storage technology is very necessary for medical drugs with high physiological activity (including raw materials and semi-finished products). The technology can not only prevent cross contamination and ensure quality, but also prevent powder exposure and ensure the safety of operators. Considering the degree of powder dispersion, usage and activity, Yamato provides a variety of special equipment for powder storage and weighing, which is suitable for pharmaceutical and nano material market.

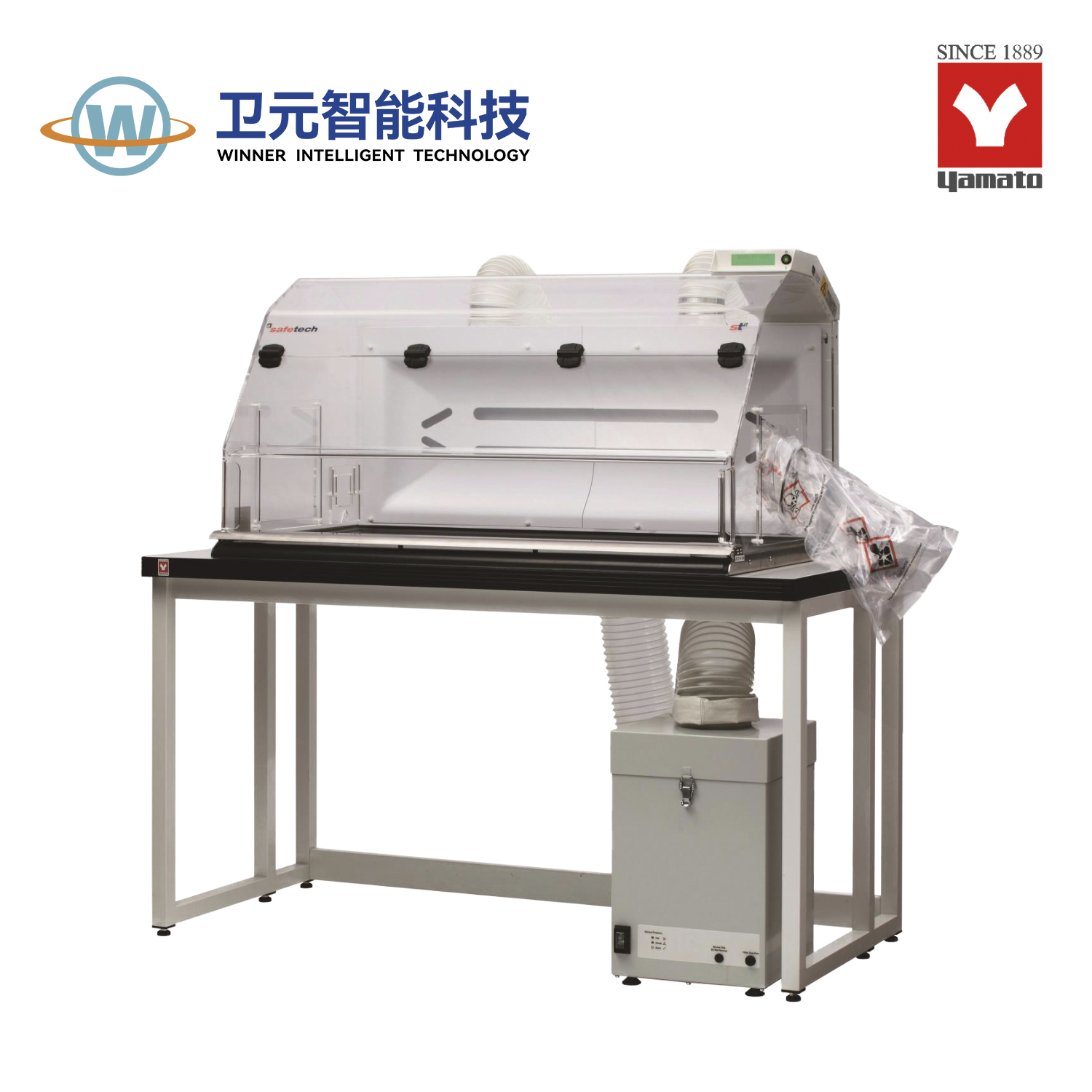

Powder storage (powder sealing equipment) weighing system ST1

Small table type fume hood for safe storage and weighing of high physiological activity powder. Energy saving, simple structure and safe and clean design are considered.

The rectifying effect of horizontal airflow from the front opening to the back can be used for micro weighing.

Only 100V power supply is required for equipment setting, and there is no need to prepare exhaust equipment separately

Stable granite working face for weighing with standard analytical balance

Standard dual air flow induction system (3-segment display of wind speed status)

HEPA filter screen with safe replaceable bag out mode

The power line of the balance can be penetrated to the outside through the left and right power line holes

Double layer waste disposal bag design can safely recycle the waste during cleaning

Storage performance: European specification en14175, American specification ashrae110

The sealing performance of safebridge powder was verified by experiments

Powder storage system stbp-1

Special fume hood for powder raw material (bulk) treatment in g-kg unit

The bulk barrel can be simply set up by the up and down adjustable trolley

Sufficient working space, easy to clean stainless steel plate is used on the working surface

Only 100V power supply is required for equipment setting, and there is no need to prepare exhaust equipment separately

Standard dual air flow induction system

HEPA filter screen with safe replaceable bag out mode

Double layer waste disposal bag design can safely recycle the waste during cleaning

Standard stainless steel stand

The insertion port of bulk barrel is equipped with local exhaust mechanism as standard

The experimental verification of the sealing performance of simulated powder advocated by ISPE was passed